The challenges of developing a human robot hand that can function with the dexterity of a human operator are frequently brought up to us at DH-Robotics. It takes careful attention to detail in mechanics, sensing, and control to build a highly dexterous robotic hand. In industrial and collaborative settings, our team aims to mimic natural hand movements while preserving stability and dependability. To ensure that our human robot hand can accomplish precise positioning, adaptive gripping, and smooth motion patterns that satisfy contemporary automation needs, each joint, servo, and motor must be calibrated to function flawlessly together.

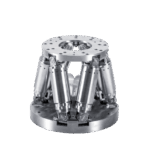

Our highly dexterous robotic hand is equipped with multiple degrees of freedom, advanced tactile sensors, and rapid response control systems, all designed to mimic human motion while maintaining durability. This combination allows us to deliver robotic hands capable of performing complex tasks in assembly, research, medical handling, and more.

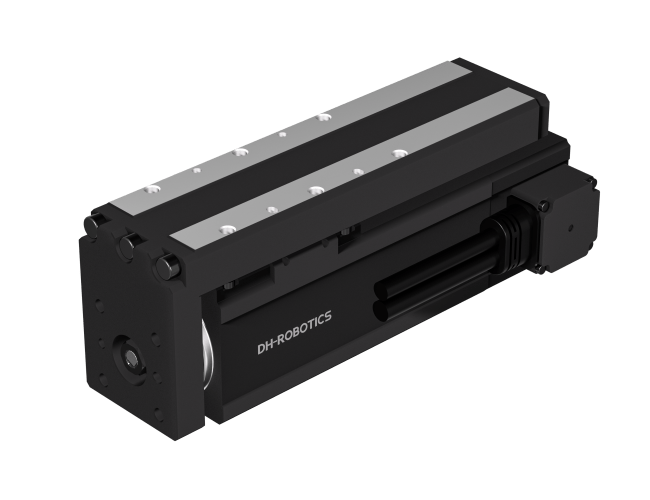

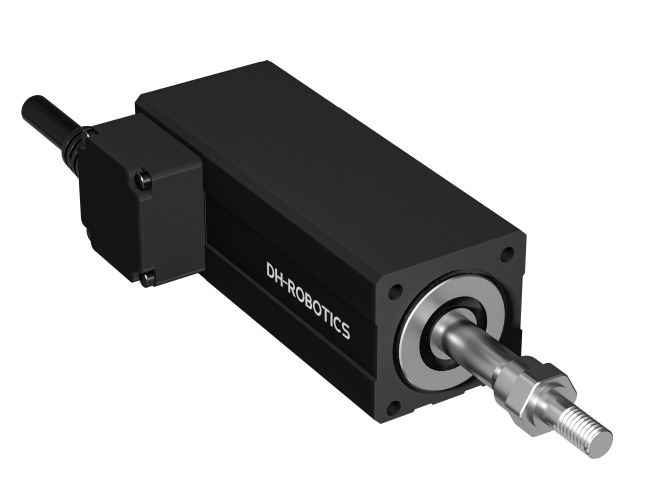

Mechanical Complexity and Motion Control

One of the main challenges in designing a human robot hand is managing mechanical complexity. Each finger requires multiple joints and degrees of freedom to achieve lifelike movement. Coordinating these elements while maintaining precision is a task our engineers take very seriously. For a highly dexterous robotic hand, it’s not just about movement—it’s about accuracy under variable loads, speed, and continuous operation.

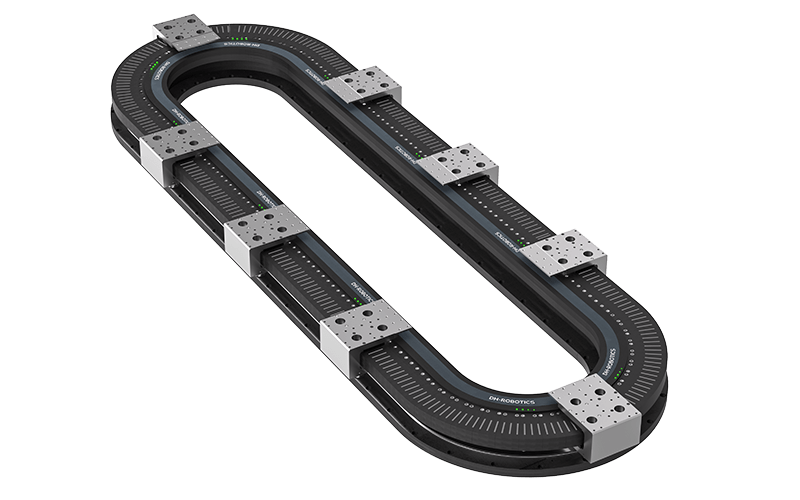

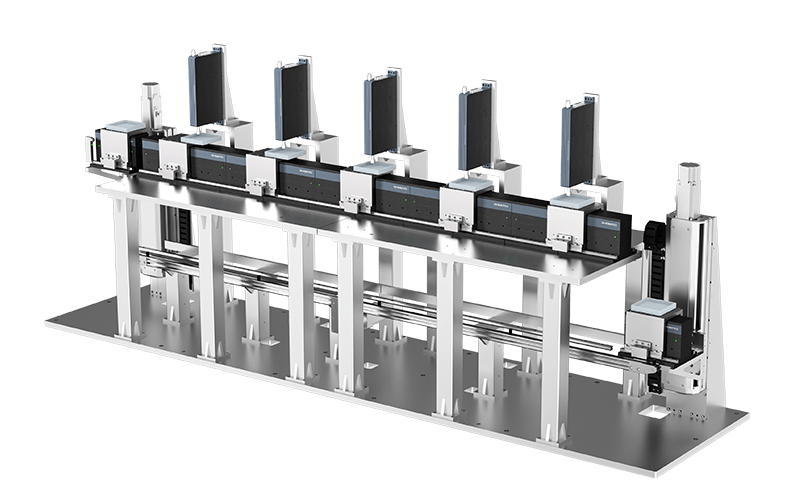

At DH-Robotics, we integrate precision motors, zero-backlash rotation modules, and direct drive technology to achieve smooth motion and high repeatability. Our hands can perform rapid cycles while maintaining gripping accuracy, making them suitable for both delicate and high-demand applications. The balance between flexibility and rigidity is critical, and we constantly refine our design to ensure optimal performance.

Integrating Sensors and Feedback Systems

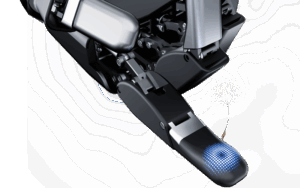

Beyond mechanics, tactile sensing and force feedback are essential for a highly dexterous robotic hand. These systems allow the hand to “feel” objects, adjust grip force, and react to environmental changes in real-time. Our human robot hand uses advanced tactile sensor arrays embedded in the fingertips and palm, enabling precise object recognition and adaptive grasping.

DH-Robotics combines these sensors with intelligent algorithms to interpret feedback and make instant adjustments. This capability reduces errors, enhances safety, and improves operational efficiency. Force feedback ensures that delicate components are handled without damage, while maintaining sufficient power for heavier or irregular objects. This level of sensory integration is what separates a basic robotic gripper from a truly highly dexterous robotic hand.

Durability and Real-World Application

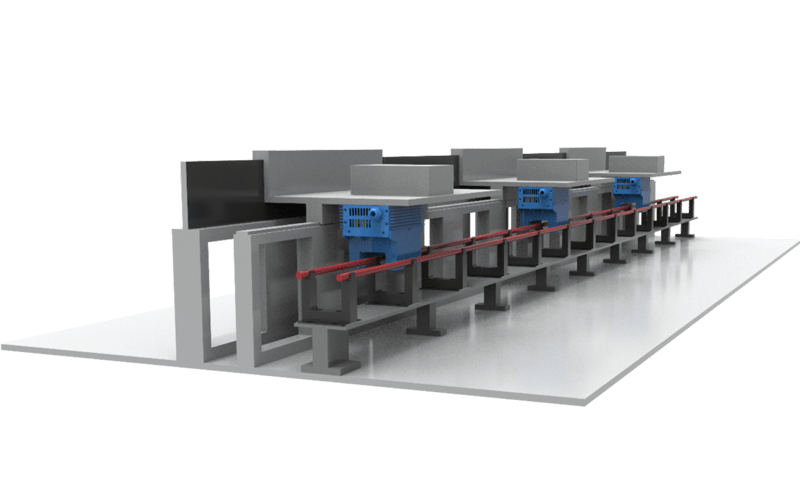

Creating a human robot hand that can sustain prolonged use while delivering consistent performance is another challenge. Our highly dexterous robotic hand is engineered to endure over one million cycles, with robust materials, precise transmission systems, and protective features that reduce wear and tear.

Applications span multiple industries, including assembly lines, medical handling, research labs, and collaborative robotics. By combining compact design with advanced feedback systems, our robotic hands can be integrated seamlessly into existing automation setups, enhancing productivity without compromising safety.

Pioneering Advanced Robotic Solutions

At DH-Robotics, tackling the design challenges of a human robot hand and a highly dexterous robotic hand is at the core of our mission. By blending mechanical precision, sensor integration, and durability, we provide solutions that are both intelligent and reliable. Our hands do more than grip—they sense, adapt, and perform tasks that were once considered impossible for robots.

With our expertise and continuous innovation, DH-Robotics continues to lead the way in advanced robotics, enabling industrial and collaborative automation to reach new heights. Choosing our highly dexterous robotic hand means investing in precision, adaptability, and long-term reliability for the future of intelligent manufacturing.