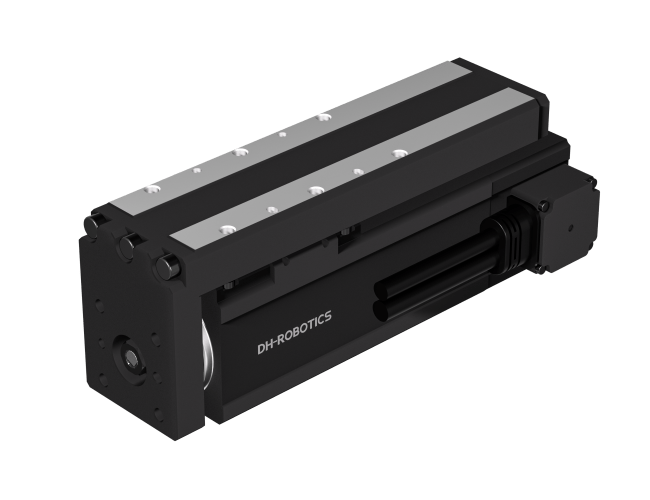

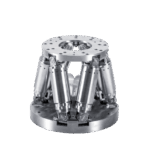

At DH-Robotics, we’ve long recognized the challenge of bridging the gap between human capability and robotic automation. Our human robot hand solutions, particularly the DH-5-6 Dexterous Hand, are designed to emulate human motion with remarkable precision. Unlike conventional robotic grippers, these dexterous hands offer multi-degree-of-freedom motion, allowing robots to handle delicate or irregularly shaped objects with intelligence and care. By integrating tactile sensing, high-performance actuators, and advanced control systems, we enable a level of adaptability that transforms human–robot collaboration on production floors worldwide.

Our team focused on creating hands that are both robust and versatile. The DH-5-6 combines precision-engineered modular design with stable control, ensuring reliability across diverse tasks. These dexterous hands empower operators to delegate complex tasks to robots confidently, improving safety and efficiency without compromising quality.

Precision and Durability in Every Movement

One of the most remarkable aspects of our human robot hand technology is the balance of strength, precision, and longevity. The DH-5-6 Dexterous Hand features an upgraded drive and transmission system, offering a gripping lifespan exceeding one million cycles. This high durability supports high-frequency operations, allowing robots to perform repetitive tasks without performance degradation.

We also designed these dexterous hands with multiple active degrees of freedom, enabling complex movements such as rotation, pinching, and grasping at varied angles. With fingertip forces reaching up to 25N and a five-finger gripping force of 80N, operators can rely on consistent, repeatable handling even in dynamic environments. These capabilities make our human robot hand suitable for applications ranging from collaborative assembly to delicate electronics handling, all while maintaining high operational efficiency.

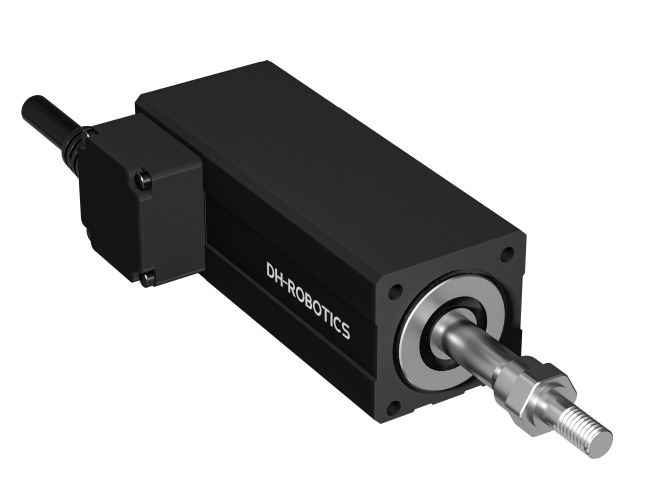

Smart Sensing for Intelligent Collaboration

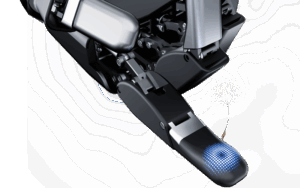

A standout feature of the DH-5-6 is its integration with high-sensitivity tactile sensor arrays. These sensors allow the dexterous hands to recognize objects, adjust gripping strategies in real time, and respond to changes in weight or shape with minimal interference. This tactile feedback ensures that robots interact safely and effectively alongside human operators.

The sensors’ advanced perception capabilities also enable our human robot hand to adapt to new tasks quickly, reducing downtime during production changes. With a response time of less than 0.62 ms and a service life exceeding five million cycles for tactile components, the DH-5-6 combines speed, sensitivity, and durability—delivering reliable performance for collaborative manufacturing scenarios.

Communication is seamless, with support for Modbus-RTU or RS485 custom protocols, allowing integration with existing automation systems and real-time monitoring. Our team designed this technology to empower operators, not replace them, creating an intuitive, safe, and highly adaptable collaborative workspace.

Robot Interaction

The integration of dexterous hands into robotics is revolutionizing how humans and robots work together. At DH-Robotics, our human robot hand solutions like the DH-5-6 provide a perfect blend of precision, adaptability, and reliability, transforming production lines into smarter, more efficient, and safer environments.

By combining tactile sensing, robust mechanical design, and multi-degree-of-freedom motion, our dexterous hands allow robots to perform tasks that were previously the sole domain of skilled human operators. This leap in robotic capability not only accelerates production but also opens new possibilities for human–robot collaboration across industries.

With DH-Robotics leading the way, the future of collaborative robotics is here—intelligent, precise, and capable of truly working hand-in-hand with humans.