The high force electric gripper has revolutionized production lines in today’s hectic manufacturing environment. Our high force gripper solutions at DH-Robotics are perfect for handling a range of components during quick production line changes because they provide outstanding gripping strength, accurate control, and dependable performance. Without sacrificing efficiency or safety, these grippers enable operators to switch between various product kinds with ease, cut down on downtime, and uphold high standards.

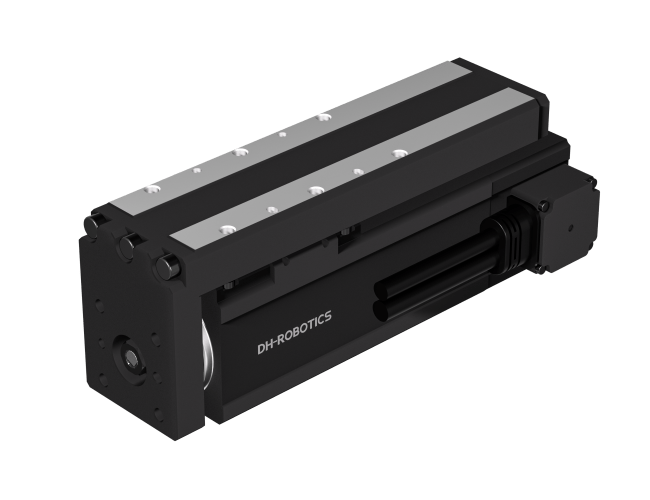

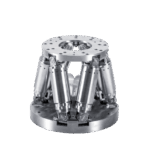

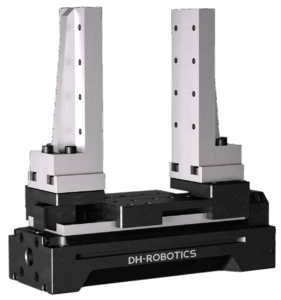

Our PGHL Series exemplifies this capability. As an industrial flat high force electric gripper, it combines a compact design with heavy-load handling and precise force control. This ensures that even the most demanding clamping requirements are met, whether you’re working with large, heavy components or delicate items requiring exact force adjustments.

Unmatched Strength and Adaptability

One of the most significant advantages of a high force gripper is its ability to handle demanding industrial applications without frequent reconfiguration. The PGHL Series delivers a single-side clamping force of up to 400N and supports loads of up to 8 kg, allowing us to tackle diverse tasks with a single device. Its generous 80mm stroke accommodates a variety of sizes, giving our team the flexibility needed to adapt to different production scenarios.

Miniaturization is also a key feature. By keeping the PGHL compact in the Z and Y directions and maintaining a lightweight body, we reduce the load and moment of inertia on robotic carriers. This allows faster, more efficient movement while keeping energy consumption low. The result is a high force electric gripper that’s both powerful and agile, perfectly suited for dynamic manufacturing environments where changeovers happen frequently.

Reliability Through Smart Design

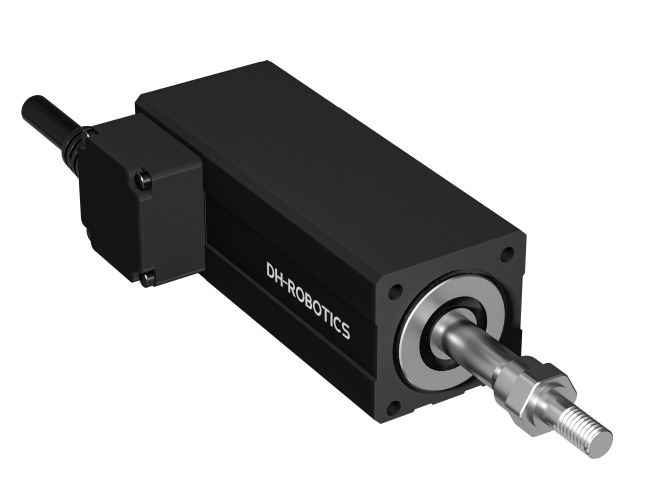

At DH-Robotics, we focus on reliability as much as power. The PGHL Series features a mechanical self-locking function, which ensures that when power is lost, the clamping force is maintained at over 95%. This prevents accidental drops of workpieces during power-down situations and provides our team with peace of mind in every operation.

The precision of our high force gripper is further enhanced through customizable parameters, allowing operators to adjust force, speed, and stroke to suit specific applications. Whether it’s heavy-duty industrial assembly, packaging, or machine tending, the PGHL Series offers a balance of strength, adaptability, and safety that standard grippers can’t match.

By integrating this high force electric gripper into production lines, we have seen tangible benefits: faster changeovers, reduced equipment wear, and improved throughput without sacrificing precision. It’s a solution that combines engineering excellence with real-world usability.

Driving Efficiency and Safety in Production

High force grippers are essential tools for modern, flexible manufacturing. At DH-Robotics, we’ve designed our PGHL Series to meet the challenges of high-speed, high-load production environments, providing both power and precision in a compact form factor. By enabling safer, faster, and more reliable handling of components during production line changeovers, our high force electric gripper solutions empower manufacturers to optimize operations, reduce downtime, and maintain high-quality output.

With DH-Robotics leading the way, our high force grippers are more than just tools—they’re strategic solutions that transform automation into smarter, safer, and more efficient production.